How can I determine the optimal lubricant for wind turbine bearing?

Selecting the optimal lubricant for wind turbine bearing is critical for maximizing the performance and extending the service life of the bearings. Here are some factors to consider when determining the optimal lubricant for wind turbine bearings:

Operating conditions

The operating conditions, such as temperature, speed, and load, can affect the performance of the lubricant. Consider the specific operating conditions of the wind turbine to select a lubricant that can withstand the demands of the application.

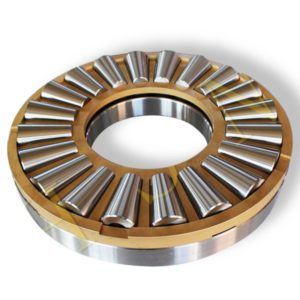

Bearing type

Different types of bearings may require different types of lubricants. Consult the manufacturer’s guidelines for the recommended lubricant for your specific type of bearing.

Compatibility

The lubricant should be compatible with the materials used in the bearing and other components of the wind turbine. Incompatible lubricants can cause damage to the bearing or other components.

Environmental factors

Consider the environmental factors, such as exposure to moisture or contaminants, when selecting a lubricant. Some lubricants are more resistant to environmental factors than others.

Certification

Look for lubricants that are certified by industry organizations, such as the American Wind Energy Association (AWEA), to ensure that they meet industry standards for performance and reliability.

Maintenance practices

Consider the maintenance practices that will be used for the wind turbine bearings when selecting a lubricant. Some lubricants may require more frequent maintenance than others.

Consult with the manufacturer or a qualified lubrication specialist to determine the optimal lubricant for your wind turbine bearings based on the specific requirements and operating conditions of your application.