How does an karl fischer moisture analyzer handle oil samples with foaming or air entrainment?

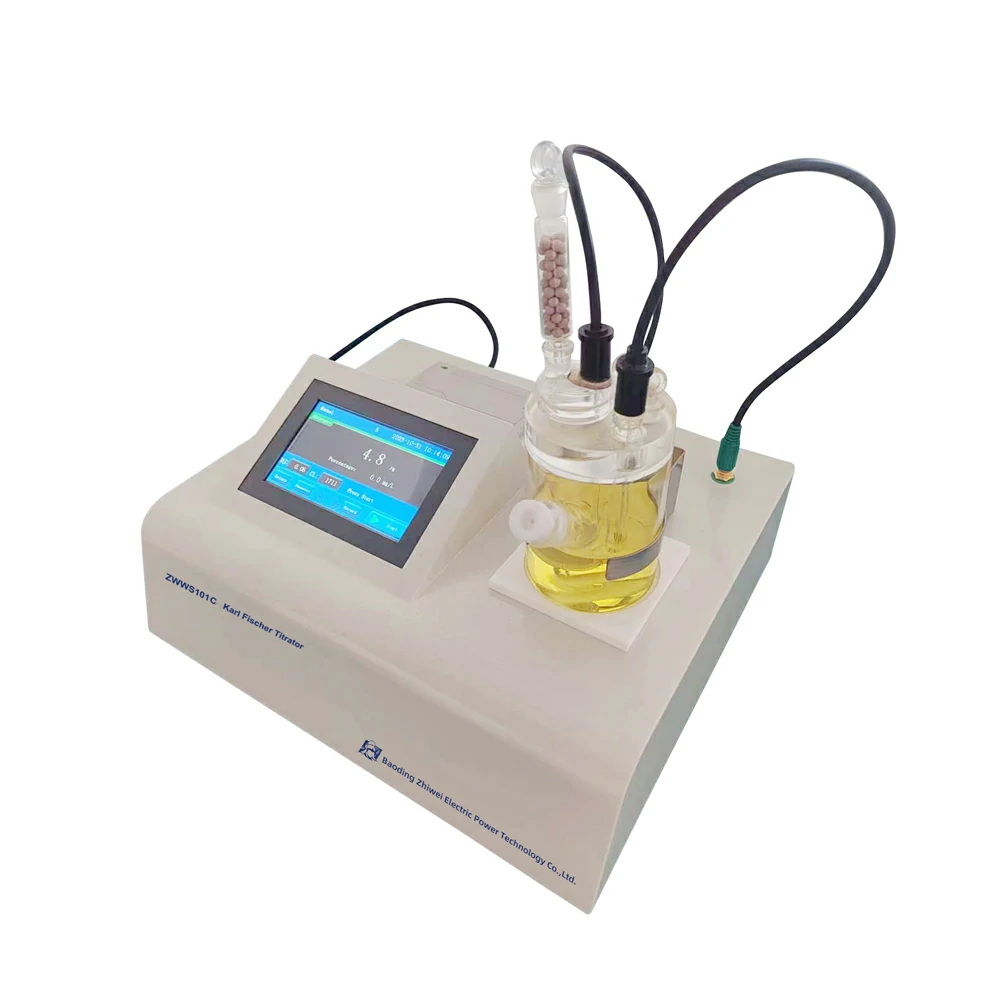

When analyzing oil samples using a Karl Fischer moisture analyzer, encountering foaming or air entrainment can present challenges that may affect the accuracy and reliability of moisture measurements. Karl Fischer titration is a widely used method for determining the moisture content in various substances, including oils, solvents, and chemicals.

Here’s how a Karl Fischer moisture analyzer may handle oil samples with foaming or air entrainment:

- Foaming Control: Foaming can occur in oil samples due to agitation, turbulence, or the presence of surfactants or contaminants. Foaming can lead to inaccurate moisture measurements by trapping air bubbles or interfering with the titration process. Karl Fischer moisture analyzers may incorporate features to control foaming, such as specialized titration vessels, antifoaming agents, or agitation control settings. These features help minimize foaming and ensure proper mixing and reaction of the oil sample with the Karl Fischer reagent.

- Degassing Procedures: Some Karl Fischer moisture analyzers include degassing procedures to remove entrapped air or gases from oil samples before analysis. Degassing helps eliminate air bubbles and ensures accurate moisture measurements by promoting better contact between the oil sample and the Karl Fischer reagent. Degassing procedures may involve applying vacuum, heating, or ultrasonic agitation to release entrapped gases from the oil sample.

- Extended Titration Time: Oil samples with foaming or air entrainment may require longer titration times to achieve complete reaction between the sample and the Karl Fischer reagent. Extended titration times allow sufficient time for the moisture in the oil sample to react with the Karl Fischer reagent, even in the presence of foaming or air bubbles. karl fischer moisture analyzer Karl Fischer moisture analyzers may offer adjustable titration parameters, allowing users to customize titration times based on the characteristics of the oil sample being analyzed.

- Calibration and Validation: Proper calibration and validation of Karl Fischer moisture analyzers are essential for ensuring accurate and reliable moisture measurements, especially when analyzing oil samples with foaming or air entrainment. Regular calibration checks, verification of instrument performance, and validation of measurement accuracy help maintain the integrity of moisture analysis results and minimize errors caused by sample variability or instrument drift.

- Data Interpretation: When analyzing oil samples with foaming or air entrainment, careful data interpretation is essential to assess the reliability of moisture measurements. Monitoring titration curves, observing endpoint detection, and verifying consistency across replicate measurements can help identify and mitigate the effects of foaming or air bubbles on moisture analysis results.

Overall, Karl Fischer moisture analyzers may employ various strategies, such as foaming control, degassing procedures, extended titration times, calibration and validation, and careful data interpretation, to handle oil samples with foaming or air entrainment and ensure accurate and reliable moisture measurements. Proper sample preparation, instrument calibration, and adherence to standardized procedures are critical for obtaining meaningful moisture analysis results in oil samples with complex characteristics.